In this final instalment on my journey in the land of Roubo, you will see how I solved 99% of my workholding problems.

I finished my bench in Roubo and me – part 2, with the goal of holding a project, a part, or a piece in any position.

Mind the gap

I built my roubo workbench with a gap. It’s simply the space between the two planks that make the bench top. A board the width of the gap, or gap stop, is used to cover the space when a continuous bench surface is ever needed. It can be removed for strategic positioning of clamped items.

Importantly, the gap can be used to place clamps in the middle of the bench nearer to the work.

I can turn the gap board up to get a smooth surface. The other side has a lengthwise rabbet or channel that I can hold work in the middle of the bench. By pushing my workpiece against a small chock of wood inserted in the gap stop, I can plane panels.

Holdfasts and vises

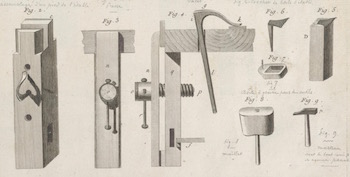

Every bench needs a holdfast or two and bench holes to hold them. Roubo illustrated a few work holding devices that are used in one form or another.

(from Roubo’s L’Art du Menuisier, The Book of Plates

Source: the New York Public Library digitized collection)

Dog holes, placed in the bench at random or in a technically calculated pattern, is a significant “device” on (in) the bench.

Holdfasts, then, are inserted in the dog holes to hold boards down anywhere on the bench. Even the bench legs have dogholes and holdfasts to accommodate long boards for jointing. And I can achieve an unlimited number of clamping positions all over the bench.

Now the work can be held steady with minimum thought devoted to how I’m going to hold it. I can concentrate on what I am doing.

Personally, I do not have a lot of dogholes in my bench. As I carry on with my woodworking, I’ve drilled a doghole or two in areas of my bench as needed, even on the end vise chops.

I installed an old school work holding vise. A new old stock 6″ Columbia vise is my end vise. It is the busiest vise in my shop. The vise and its thick wood chop have stood up to all work holding I’ve thrown at them.

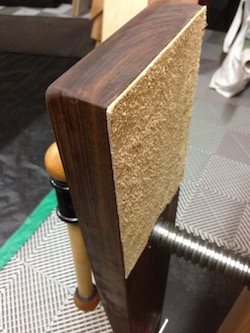

Leg Vise

I made a leg vise from a walnut plank with cast steel acme threaded screw. A purpleheart parallel guide with peg holes allows adjustments for various board widths and strong, balanced clamping.

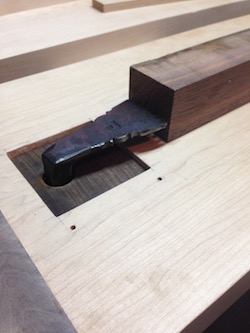

Bench Hook

Another workholding aid: blacksmith forged iron bench hook (aka plane stop) for even more ways to hold a work piece in place.

And when all else fails…

I have a handful of clamps.

But, when there aren’t enough for a project, I use bungees. Yes, bungees do very well in a pinch and a twist. I believe you can have too many clamps contrary to the popular mantra expressed by a lot of woodworkers.

I have enough for this small space. I kid you not when I say I do not want any more clamps!

Last Thoughts

This was a peaceful build and one more flagstone on my path to self-knowledge.

My bench is not an exact copy of the classic roubo bench style but it is what I needed going forward in my work. I made it to fit my skill level and needs. Constructed of primarily maple and walnut, it is heavy and very sturdy. It is compact, too, which suits me perfectly.

I had only a few hand tools. I discovered that my hesitation was due to lack of information, not lack of skill. I was afraid to take the project on. It took a few years to decide to do it. But I inched my way through that fear, hesitation, and possible failure.

Now, I have a bench.

❤️Shirley J

•

This is part 3 of 3 in the Roubo bench build series. Here are the others: