The fret saw is one of my favorite tools. With it I can make delicate cuts on thin wood veneer. This was a valuable quality that helped me complete the Dan mask marquetry project.

Occasionally, I’ve used the fret saw to finish dovetails.

One irksome aspect of the tool was the handle. Mind you, it is not a fault of the tool. I believe that years working with my hands since childhood left me with “big” fingers. How does this relate to the fret saw?

The original fret saw that I purchased has a handle that is just too small for me. When I use it, the end or heel of the handle digs into my palm. I imagine that I could change the way I hold it while cutting. Somehow, it is difficult to manipulate veneer or whatever I am cutting and wield the fret saw at the same time.

More than once, I considered changing the handle, but I was not really sure if I should do that. I knew that the tool’s resale value could possibly decrease. However, the tyranny of resale value was not going to deter me here. I focused on the need at hand (pun intended) and changed the handle.

Disassembling the Fret Saw

I have to admit that the thought of potentially destroying the handle or the tool was daunting. Being left with a small heap of wood and metal made me nervous. I had to do it, however. I had to see if the handle could be removed.

The mystery to solve was this: was the saw “tang” serrated or tabbed? Was it locked in with glue? Was the tang short or extended through the entire handle? Maybe I was overthinking this.

I snipped the metal ferrule and used pliers to remove it from the handle neck. The wood remained stable except for a very small area on the neck that was crushed. There was no returning from that. If I stopped here, I would have been left with a potentially weakened tool.

I kept going.

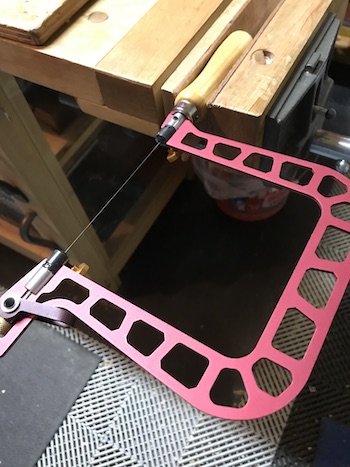

Aided by a small machinist’s vise, the tang came up and out of the original handle by simply leveraging the saw frame.

The tang dislodged easier than I thought!

This is what made me procrastinate for so long? This? Well, I was surprised, relieved, and ready to make a new handle.

The Successor

Ash was perfect for the replacement. The wood is strong and dense for flooring, baseball bats, and tool handles.

After sawing the blank close to size, I used a rasp to get an ergonomic shape that was pleasing to my hand and eye.

Further refining.

The fit in my hand was crucial. Any “disagreements” were rasped away!

The new handle is 1-1/4″ longer than the original.

Reassembly and Renewal

The usual finishing touches were made, including:

- drilling the hole for the tang,

- shaping the neck for the ferrule,

- coating the wood with shellac.

Finally, the tang was fitted and glued into the new handle. The irony is that the original configuration was not glued at all. Otherwise, it may have been more difficult to remove the old handle.

And the original handle? Here it is on a frame saw file.

The large handle hole is convenient. It keeps the saw from getting away from me while using it. I can put my finger in the hole to prevent the saw from slipping.. And I like the way it looks.

Now, the renovation eliminates any reason to hesitate using the fret saw. I have an idea in mind that will be revealed in a later post!

Baadaye

Shirley J ❤️

2 thoughts on “● A New Fret Saw Handle”

Another job well done, keep up the good work.

Thanks so much for reading, Kelvin! More projects are in the works.

Comments are closed.